3D數位電路板設計暨智慧製造類產線工廠

3D數位電路板設計暨智慧製造類產線工廠

3D Digital Circuit Board Design & Intelligent Manufacturing Factory

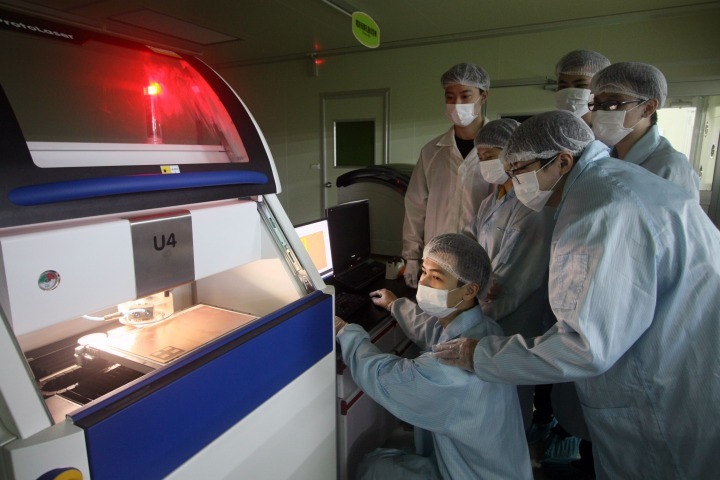

印刷電路板(PCB)產業是國內電子產業中非常重要的基礎產業,有鑑於PCB產業及SMT智慧製造70%的人才需求均集中在北部,因此,本校獲得教育部「產業菁英訓練示範基地」計畫補助,成立「3D數位電路板設計暨智慧製造類產線工廠」,於2018年10月正式揭牌啟用,是全國大專校院唯一的3D數位PCB及SMT智慧製造類產線示範工廠。

The printed circuit board (PCB) industry is crucial to domestic electronics. Seeing that 70% of the human resource demand for the PCB industry and SMTintelligent manufacturing is concentrated in the north, the school received the Ministry of Education’s“Industrial Elite Training Demonstration Center” program subsidy. It established a 3D Digital CircuitBoard Design and Intelligent Manufacturing Factory. The site, officially inaugurated in October 2018, is the only 3D digital PCB and SMT intelligent manufacturing production line modeling factory in Taiwan.

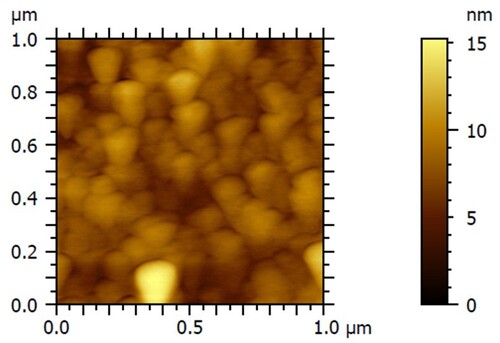

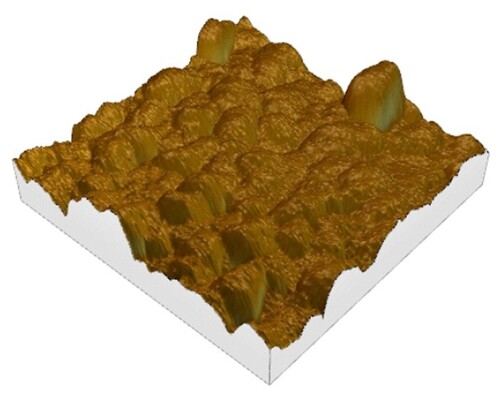

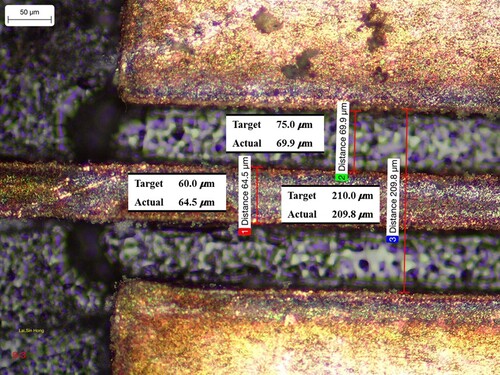

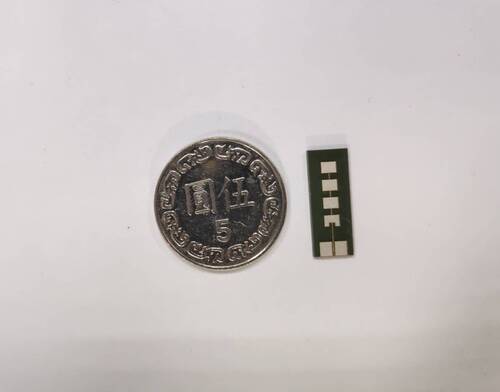

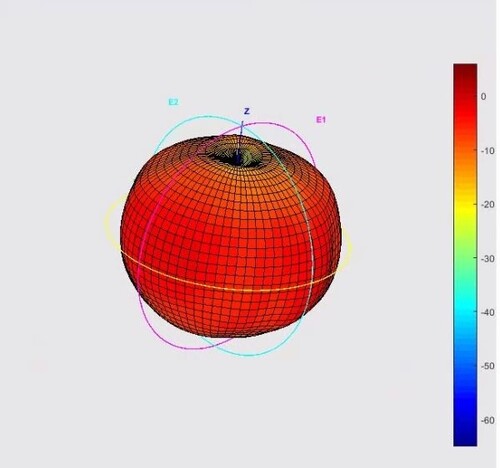

3D數位電路板設計暨智慧製造類產線工廠建置的「PCB-SMT」產線,具有先進的「PCB無光罩之雷射直刻製程」與「智慧化SMT表面黏著技術」,產線設備與業界同步,可在校進行微量產。過去技職學生在工廠實習時,往往只學到單獨的機台操作與製程,而在類工廠產線上可以完整的整線式實習,累積經驗,將來畢業後即能無縫接軌,順利踏入職場就業。

The “PCB-SMT” production line built by the 3D DigitalCircuit Board Design and Intelligent ManufacturingProduction Line Factory featured an advanced “Photo-mask-less laser direct engraving PCB” process and intelligent SMT (Surface-mount technology). The production line equipment is the cutting edge used in the industry, allowing schools to produce products on a small scale. In the past, when vocational college students interned in factories, they often only learned the operation and process on separate machines. Now they can complete the one-stop internship on the production line in an environment similar to factories, accumulate experience, and seamlessly integrate their expertise into the workplace after graduation.